News

Electronics and semiconductor industry

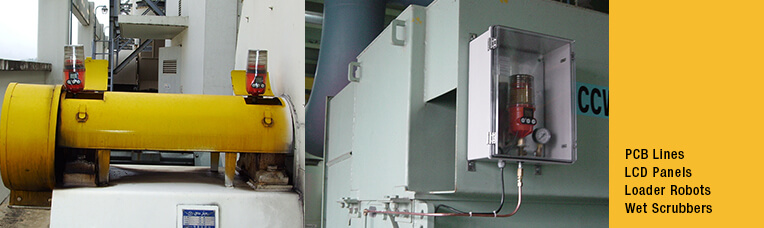

Automatic greasers can be used on internal equipment such as loaders, conveyors and electric motors, but are mainly installed on wet scrubbers and AHUs (Air Handling Units) and cooling towers of the HVAC system.

Maintaining cleanliness, constant temperature and constant humidity is very important due to the particularity of the semiconductor production plant. The AHU (Air Handling Unit) and the clean room are the most prosperous area for the greaser. Recently, automatic grease lubricators are installed directly on the production line as an automatic storage system, an LCD panel robot transfer system and LM block, etc.

Since many toxic materials are used in the manufacturing process of semiconductor systems, it is essential that workers are not exposed directly to these hazardous substances. Most semiconductor fabrication structures employ exhaust gas management systems, such as wet scrubbers, burners, heated absorbent cartridges, etc., where mainly grease fittings are installed.

> Main lubrication points

Because of the clean working conditions, dust, temperature, humidity, most machines are lubricated for the air handling unit, dust collector, scrubber. Before the introduction of electromechanical lubricators on the market, the gas lubricator was popular, but reliability decreased due to temperature and humidity inside the air handling unit. The main users are the electronics industry of Korea, Samsung, LG, Hynix, the Dongbu electronics uses an electromechanical lubricator.